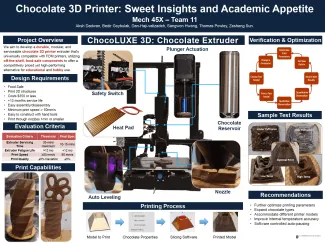

Aksh Dadwan, Bedir Goybulak, Danial Haji-valizadeh, Sangwon Hwang, Thomas Powley and Zesheng Sun

- Degree:

- Bachelor of Applied Science

- Program:

- Campus: Vancouver

Our design solution and process

Our client was Dr. Ahmad Mohammadpanah, a mechanical engineering professor who proposed the project and set out the initial requirements in terms of print speeds and nozzle diameters. However, this project was always about more than building and testing a chocolate 3D printer.

One of our goals from the outset was to empower non-technical people to build their own printers by providing them with a “recipe” of easily accessible components, instructions on how to assemble the components, and guidance on how to use the printer to produce their own edible creations.

The ChocoLUXE 3D printer consists of a FDM printer, a 3D-printed extruder that can be easily attached to the printer and a secondary reservoir to melt the chocolate as preparation to reload the extruder when it empties.

Throughout the design process, we were careful to choose components that would be readily available and easy to assemble by the end user.

There are 3D chocolate printers available, but they cost around $1500 or more, and they are not open source.

In our solution, about 88% of the components are off the shelf or 3D printed.

Only a few components need modification with a few simple hand tools that most people would likely have. Users can use their existing 3D printer to build the housing into which all the components are fitted. Assuming you already have a 3D printer, our components would cost you around $350-$400.

What we’re most proud of

We all really enjoyed working with our client on this project.

His expertise in additive manufacturing meant that he had firsthand understanding of the engineering product design process and how much work and time is required to design, test and build a product like this.

It was very rewarding to work together as a team.

And it was great to be designing and building something tangible, where we could immediately identify the shortcomings of our ideas and see where we were on the right track.

The accessibility component of this project also meant a lot to us. We’ve built a product that we can use to 3D print chocolate creations. But more importantly, we’ve created instructions so that other people can build their own 3D chocolate printer at a reasonable cost and with minimal effort.