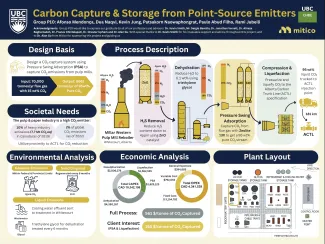

Paulo Abud Filho, Rami Jubeili, Kevin Jung, Afonso Magalhaes, Patsakorn Naowaphongrat and Dua Naqvi

- Community Partner: Mitico

- Degree:

- Bachelor of Applied Science

- Program:

- Campus: Vancouver

Our design solution and process

Our client, Mitico, has developed a carbon capture technology that is based on temperature.

They asked us to explore if we could design a comparable system based on pressure.

Research has shown that pressure swing adsorption could be a better approach in some applications because it can be done at lower temperatures and is more efficient at capturing carbon dioxide.

We developed our solution using real data from the Millar Western Pulp Mill in Whitecourt, Alberta, although our design could be applied to any other pulp mill or high-emitting facility.

Our system captures CO2 emissions from the recovery boiler. We then purify the gas through a desulphurization and dehydration process to meet the specs required by the Alberta Carbon Trunk Line. The gas is then put into the pressure swing adsorption unit where the CO2 is separated out using zeolite packed beds that absorb CO2 at certain pressures. We then compress and liquefy the captured CO2 so it is ready to be shipped.

The second part of our work was to explore the economic feasibility of the solution and conduct a sensitivity analysis with different levels of government funding.

Some of our initial process designs were far too expensive to be feasible, but we pursued different strategies to reduce costs by more than half.

What we’re most proud of

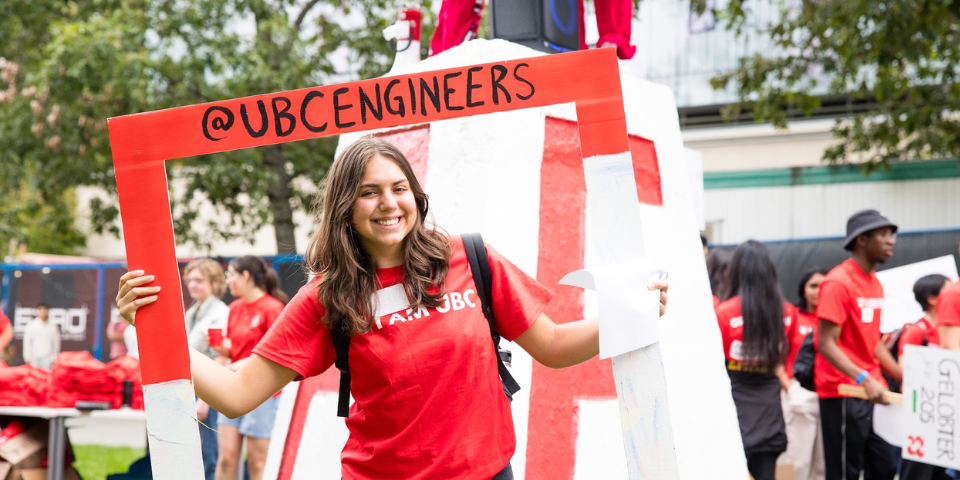

We approached this project as a true team.

We all brought knowledge or skills from our previous experiences, exchanged ideas as a group and built on them together, and respected everyone’s perspectives.

Our collaborative work on this project felt like we were running our own engineering consultancy, and it made us excited for our future in engineering. Thinking back to where we started in September and where we’ve ended up eight months later is something we’re very proud of.

Our skills also grew over the year. There were so many elements to this project: drafting instrumentation diagrams, calculating process control strategies, performing an economic feasibility analysis, doing a hazard assessment, ensuring our outputs met the pipeline specs and that the operation met regulatory requirements.

Throughout it all, we benefited so much from our profs – Dr. Kevin Smith and Mr. Sergio Berretta.

They always found time to meet with us and ask us the questions that really made us think about our ideas and enabled us to come up with a better design solution.

Dr. Kevin Smith Mr. Sergio Berretta