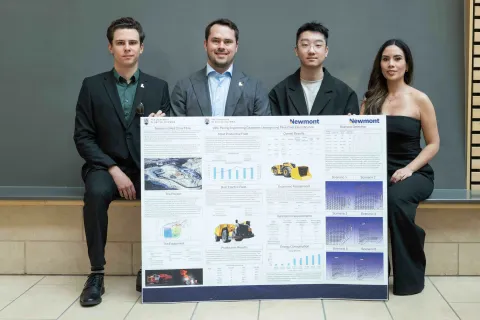

Endo Cui, Gabriel Demers Angelica Gonzales del Valle Solis, Billy Ruan and Tom Terblanche

- Community Partner: Newmont Corporation

- Degree:

- Bachelor of Applied Science

- Program:

- Campus: Vancouver

Our design solution and process

We began by looking at the equipment (trucks and load haul dump (LHD) loaders) that would be required to move 40,000 tonnes of ore per day, reviewing options for a diesel fleet, a hybrid fleet and a fully electric fleet (including both battery electric vehicles and tethered options).

After selecting the vehicles required for the operation, we used a program called HaulSim to build simulation models of how the equipment would function over the proposed mine life of just over 30 years, taking into account different phases of production through different areas of the mine.

We also looked at auxiliary requirements for the different fleet types. For example, while electrical equipment requires charging stations, diesel equipment requires fuelling infrastructure as well as extensive ventilation systems.

Our economic analysis looked at capital and operating costs for the three main scenarios, and we also conducted an environmental analysis of the options. Ventilation costs associated with the diesel fleet were a major factor in shaping our final recommendation.

In the end, we proposed a tethered LHD solution as there are no battery electric loaders large enough to manage the volumes of ore that need to be moved. Our proposed solution will require modifying the mine design given that tethered equipment restricts maximum haulage distance and may require redesign of the tipple access.

Our secondary recommendation if Newmont is looking for a fleet that could be implemented without requiring modifications to the mine design is a hybrid fleet.

What we’re most proud of

This project exemplifies the power of collaboration.

We worked well as a team and we enjoyed collaborating with our contacts at Newmont, who included one of the directors of innovation and a business development lead. We also benefited from input from our professors and representatives from Sandvik, an equipment company that provided some simulation data.