Raeiti Azarkeyvan, Perry Chahal, Katrina Lang, Parsa Mivehchi, Harris Rana and Elyse Wong

- Community Partner: Teck Resources

- Degree:

- Bachelor of Applied Science

- Program:

- Campus: Vancouver

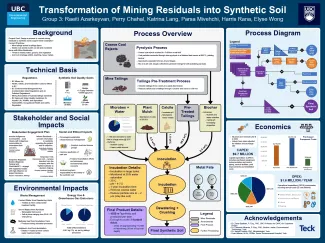

Our process

We began with an extensive literature review to understand what’s been done to date in this area. Converting mine residuals to soil is a fairly new concept, with most of the work being done at the lab scale and not applied operationally. There were two papers in particular that we found very helpful, and we took elements from each to develop and scale up a process to convert mine residuals into soil capable of growing vegetation.

Our process begins with pyrolysis to convert coal particles into biochar.

Byproducts are separated into bio-oil (which is sold) and biogas (which is collected to generate energy to create for a self-sustaining pyrolysis process).

Tailings are pre-treated through a dewatering and crushing process. The tailings and biochar are then combined with microbes, water, plant mulch and calcite and incubated in large tanks over a one-year period. The resulting particles are then dewatered and crushed to produce a synthetic soil. Our process is capable of producing 4,550 m3 of synthetic soil annually from an input of 3.080 m3of mine tailings, and the resulting product meets specific quality goals in terms of pH, moisture, selenium and iron content, and carbon to nitrogen ratio.

Our design solution includes a layout of the facility and list of equipment, calculations of energy and water requirements, and an economic assessment of capital and operating expenditures.

We also developed an engagement plan with Indigenous communities and regulatory bodies.

What we’re most proud of

It’s very exciting to demonstrate that it’s possible to convert something that has been characterized as a waste into a useful product.

We’re proud of how much we learned over the course of the project. We didn’t have prior experience in the mining sector or with microbes, requiring us to do a lot of independent learning that we then integrated and applied to come up with a workable solution.

We benefited from a strong relationship with Teck Resources, our industry partner. They were fantastic at providing us with data, answering our questions and checking in with us regularly. It enabled us to get a much better sense of the mining industry and what’s being done to operate sustainably.

Finally, it was wonderful to be part of a great team where every single member was invested in the project and committed to doing good work on it.