Caelan Accili, Ben Alberga, Carla Conradie, Audrey Lee and Cameron Shepherd

- Degree: Bachelor of Applied Science

- Program:

- Campus: Vancouver

Our design process

There is currently a temporary system in place to treat the contaminated groundwater, but it can only run half the year – which is doubling the treatment time – and operates by pumping the water from the tailings ponds underground into storage tanks. However, we know that the arsenic trioxide waste will eventually find its way through groundwater movement up into a local water body.

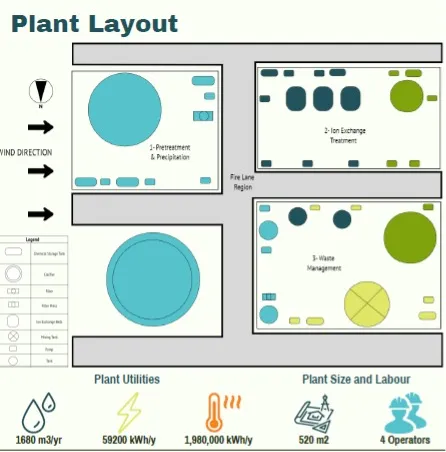

Our plan is to take the groundwater – which currently has 49 mg/L of arsenic compared to allowed levels of 0.01 mg/L – directly from the underground reservoir, pumping up a flow of 2,600 m3/day through a C shaft into our plant for treatment. Our process starts with a flow equalization tank to provide stable flow for the downstream treatment process. The next steps are oxidation and precipitation, and clarification and filtration. A two-step ion exchange process first targets arsenic and antimony and then isolates zinc and lead. These chemicals are then sent to waste treatment and the treated effluent is pumped and discharged to Yellowknife Bay.

We developed a plant layout for our planned process that estimates water and energy requirements, as well as facility size and required labour. We also completed an economic analysis to estimate the capital and operating costs over the 20-year life of the plant.

The social considerations of this project were very important to us, particularly given the history of this mine in the community. We developed a stakeholder engagement plan with Indigenous Peoples and residents, local government and regulatory boards.

Integrated Water Management at UBC

Our project’s future

The federal government is currently managing the site and has a treatment plan in place. We may decide to send our final report and recommendations to the group currently overseeing the project