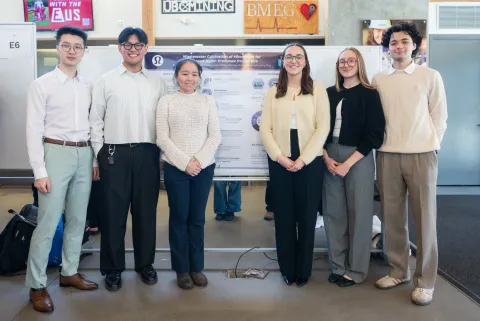

Isaiah Colina, Emma Harris, Kate Lindsay, Matthew Mulia, Jessica Sun and Henry Ting

- Community Partner: lululemon

- Degree:

- Bachelor of Applied Science

- Program:

- Campus: Vancouver

Our project

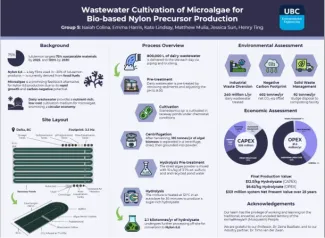

As part of its effort to reduce its reliance on fossil fuels, lululemon has set the ambitious goals to use preferred materials and end-of-use solutions to support ad advance a circular economy. This journey will require shifting away from some of their existing materials or finding new ways to make other materials, including nylon, a synthetic polymer used in the company’s clothing and that is traditionally made by processing petroleum into building block polymers.

We collaborated with the innovation team at lululemon to develop a microalgae cultivation and harvesting process that produces hydrolysate, a feedstock that can be used to produce nylon via a biomanufacturing process.

In addition to supporting lululemon’s goals, our process makes use of wastewater from dairy processing plants, thus providing a value-added use for wastewater.

The challenges we faced

We needed to learn a lot to work on this project – from understanding how the biochemistry works to figuring out if it was technically feasible to produce large volumes of hydrolysate within our production facility.

This is an emerging area of research and comparable applications are being done at a very small scale. We had to do a lot of literature reviews and calculations to arrive at our solution.

This project was unlike anything we’ve worked on in our degree. Many projects we’ve worked on prior to this were relatively straightforward and required us to apply practices that had been successfully used in other applications. This was an open-ended project where it was up to us evaluate and assess potential ideas and solutions. We think we did a good job of narrowing the scope, understanding our client’s needs and coming up with a feasible and innovative solution.

Our project’s future

This project could serve as a foundation for further exploration into the scalability and adaptability of microalgae-based materials across different industries, including the textile industry.

We’re excited to see the continued adoption of processes utilizing waste streams to produce sustainable materials over the next few years, and we’re proud to think we may have contributed in some small way to advancing sustainability efforts across the industry.