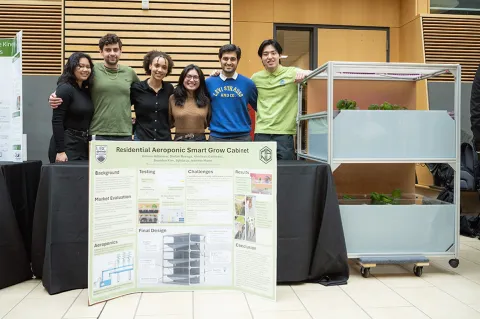

Kihomi Adhémar, Stefan Busaga, Akhilesh Gattineni, Brandon Kim, Sylvia Ly and Jennifer Mane

- Community Partner: Genoptic

- Degree:

- Bachelor of Applied Science

- Program:

- Campus: Vancouver

Our design solution

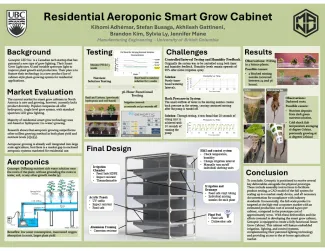

We began by doing research to better understand this particular market.

We discovered that aeroponics is at the pinnacle for agricultural applications because it minimizes water use, maximizes growth and results in hardier plants that are less prone to disease. Interestingly, there are very few applications for smaller-scale systems at the consumer level.

This led us to the decision to design a mini-greenhouse, or cabinet, that would run autonomously to grow microgreens, featuring Genoptic’s patented lighting technology. Their LED grow lights use AI to provide tailored illumination depending on the plant’s growth cycle.

We designed a structure to include multiple shelves for plants, a thermoformed irrigation chamber, and food- and dishwasher-safe 3D-printed pods for the plants.

We designed an automatic irrigation system and did the electrical design, including sensors for real-time monitoring of temperature and humidity. The system also includes a Human-Machine Interface (HMI) display.

Although we developed design drawings for a full-scale cabinet, the prototype we built and tested is slightly smaller.

What we’re most proud of

Manufacturing is an interesting program because it brings together so many different kinds of engineering and is positioned at the intersection of mechanical, materials and, in this case, some electrical engineering and coding.

We had to draw on knowledge we’d acquired throughout our degree, and we also had to learn some new skills, which was very rewarding.

Over the course of the project, we overcame a lot of challenges, learned new systems and did good engineering work.

It was quite something to go from an idea in our head to a physical product by going through all the stages of the design cycle, from ideation and market research, to design, prototyping and testing. It was also very rewarding to work with our client and integrate their feedback into our solution, which could ultimately be manufactured and used by people who want to a stress-free way to grow microgreens in their homes.