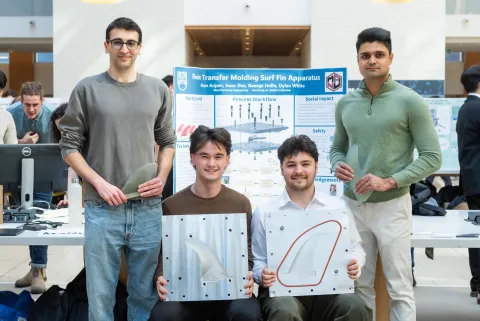

Kian Anjam, Isaac Dee, George Hollo and Dylan White

- Community Partner: Manufacturing Engineering

- Degree:

- Bachelor of Applied Science

- Program:

- Campus: Vancouver

Our project

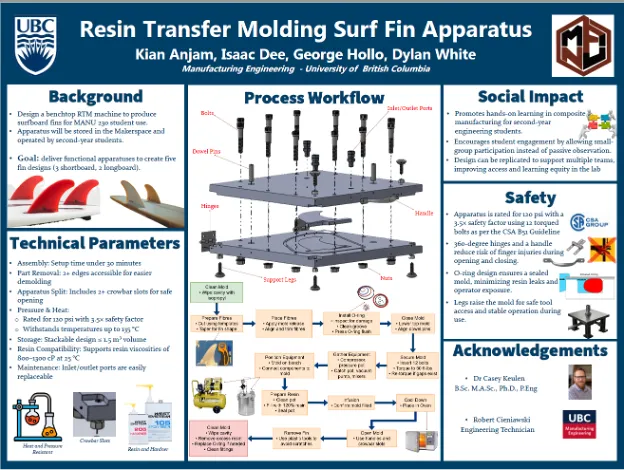

In their second year, Manufacturing Engineering students take a course where they get a hands-on introduction to the most common manufacturing processes. One of the only processes they don’t get to do themselves is resin transfer moulding. This is a composite manufacturing process where you fill a mould with layers of carbon fibre or fibreglass, infuse it with resin under pressure, and then cure it to create a solid, lightweight durable product.

This part of the course is currently taught as a demonstration where students watch a technician and professor explain the process and do it in front of them.

Our client asked us to design a benchtop resin transfer moulding apparatus that students could use to produce one of five unique surfboard fins within the time constraints of a standard lab period and with minimal assistance from the lab tech.

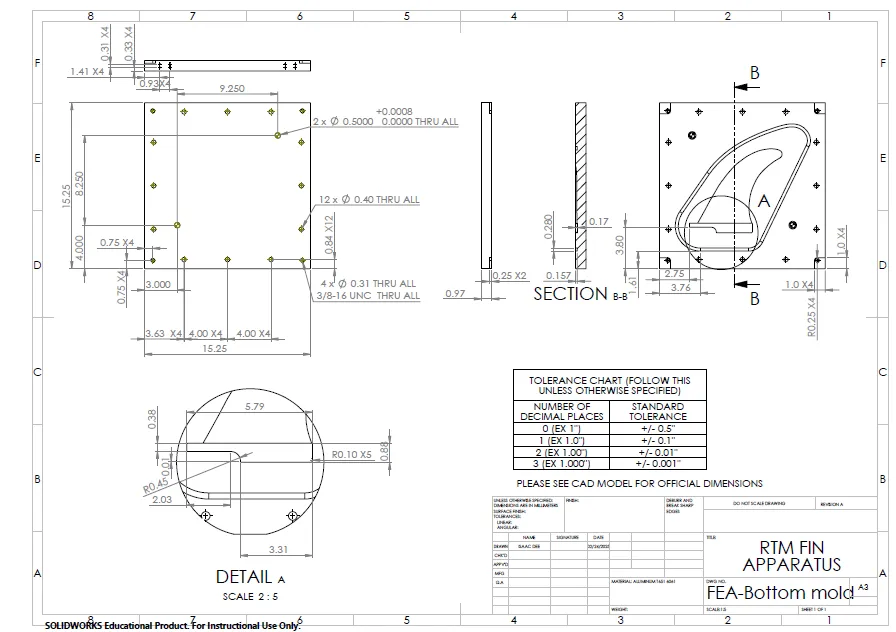

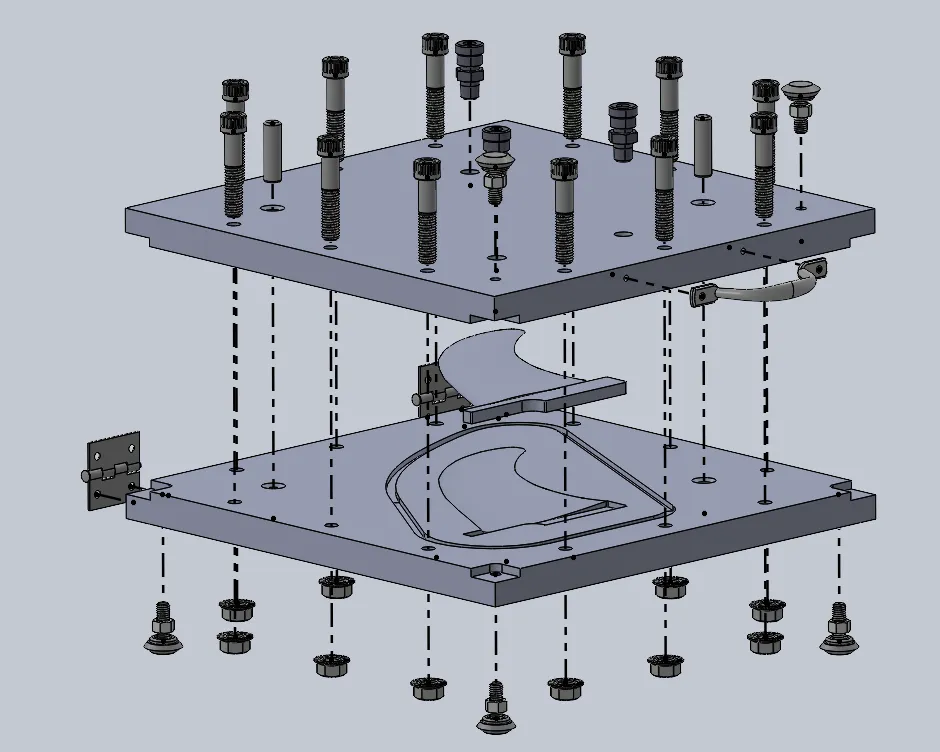

On the apparatus side, we explored and assessed potential solutions for the mould itself, including deciding how the apparatus would open or close, a mechanism for keeping it open during material layup, and the clamping mechanism. We also needed to design a system that could be stored easily in the Manufacturing Lab Space, where space is at a premium.

Throughout the design stage, we had to consider our end users. The process needed to enable students to gain hands-on experience with resin transfer moulding. As such, we didn’t want this to be a perfect solution.

This is a learning tool for students and we wanted to make sure that students could play around and experiment with different parameters so that they were engaged in the process and achieved specific learning outcomes. Safety was also an important consideration, and we conducted extensive safety calculations, including failure modes and error analysis.

We also built out templates for the fabric that needs to be cut. We found a solution so that students – rather than the lab tech – will be able to do this quickly themselves during the lab. Finally, we developed a cost of materials (including required labour costs for the machinist) and a comprehensive user manual outlining the step-by-step procedure for students to follow.

The challenges we faced

As mentioned above, one of the main challenges we faced was designing the final fin shapes in code. Although we did a lot of research and talked with experts in the area to come up with a solution, it just wasn’t working. We ended up developing a solution to generate the surfboard fin profile shape in ImageJ, used Excel to generate the points and then imported the points into SolidWorks.

As part of this pivot in our approach, we had to go back to our client and explain why the initial plan wasn’t feasible. Because of the close communication we’d established throughout the project, the client understood why we needed to change our original process.

Exploded view of assembly:

What we’re most proud of

We’re proud of how we worked together as a group, with each of us taking on tasks that complemented our specific skill sets. Looking at our end result, we feel we accomplished a lot as only four engineers.

We’re also impressed by our ability to pivot when things weren’t working, such as with the coding issue, and for our ability to test out different options to come up with the best solution.