Noor Ali-Mohamad, Beatrice Boersig, Bhavya Nagda, Rachael Nicholas and Jane Wu

- Degree:

- Bachelor of Applied Science

- Program:

- Campus: Vancouver

Our design solution

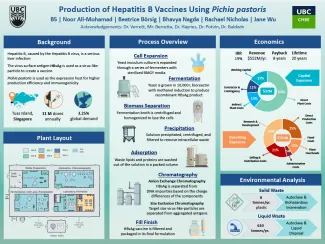

While vaccines based on hepatitis B virus-like particles have been developed, our project is unique in that our process has not previously been used for the hepatitis B vaccine and some of the separation techniques we’re proposing have not yet been done at an industrial level.

Our design solution was developed based on extensive research on virus-like-particles, vaccine production and various separation and purification methods.

We synthesized this research to create a target process and then scaled it up to an industrial facility capable of producing 11 million doses of vaccine annually, representing more than three per cent of global demand.

Our solution is not just focused on biological engineering. We also assessed the environmental context, developed a layout for the plant (and its more than 70 pieces of equipment), proposed hazard management measures and conducted an economic analysis.

This analysis showed that our plant would have a gross revenue of close to $550 million per year and provide a high rate of return despite our high operation costs because we are relying on a lot of single-use equipment that must be disposed of after each batch.

What we’re most proud of

We’re very proud of our ability to come up with an innovative process to create an effective vaccine.

In many ways, it was a good summary of our degree as a whole, enabling us to apply concepts we’ve learned in all our courses over the past three years. It made us appreciate the scope of our knowledge base and know that we can translate that into a feasible, large-scale facility to produce a valuable vaccine.

We worked on this project collaboratively, with each of us contributing to each part of the process rather than splitting up the work by our particular specialization or expertise. This approach to team work meant that we’ve all expanded our knowledge and skills, and it brought us together as a group.

We’re also impressed with the economics of our proposed solution. We took something very low value – yeast – and were able to turn it into a high-value product that is important to human health. Our proposed process and production facility generates significant annual profit, which could be invested in research and development or health-care initiatives.