Jenny Chen, Alan Chow, Geoffrey Lam, Jason Sugiharto, Eleanor Walton-Knight, Susan Xu

- Community Partner: Hatch

- Degree: Bachelor of Applied Science

- Program:

- Campus: Vancouver

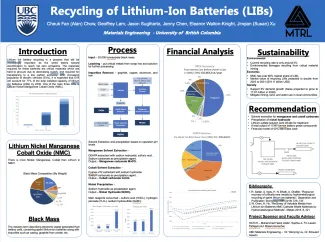

Our process and the results of our analysis

We worked on this project with Hatch, a consulting engineering firm. They asked us to develop a solution that could recover metals from a total annual input of 30,000 tonnes of black mass (the waste generated from battery cells, which includes both the useful metals and various impurities).

Our process removes the impurities – like graphite, copper, aluminum and iron – and isolates the metals we want: nickel, lithium, manganese and cobalt.

This process consumes reagents including sulfuric acid, hydrogen peroxide and sodium hydroxide. It uses solvent extraction to isolate manganese and cobalt carbonate and precipitation to isolate for nickel hydroxide. The lithium sulfate solution is sent offsite for treatment.

Once we had landed on a workable process and identified the mechanical equipment needed to support our operation, we did a feasibility study to assess if our proposed plant was economically viable.

This included costing out both capital expenditures and operating expenditures in terms of reagents, labour and maintenance materials.

What we’re most proud of

Each of us made significant contributions to different elements of this project. There’s a lot of pride that comes from looking at the process flow diagram or feasibility study, to take just two examples, and knowing your role in putting that together.

We were also a very strong team and supported each other throughout the year. Finally, this project was a lot of fun.

In many ways it felt like we were operating like a consulting firm working with a client – which is what many of us will likely end up doing after we graduate!