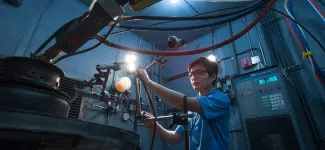

What’s it made of and why? If you ask these questions about the products that surround you or dream about creating the building blocks for substances that haven’t yet been invented, you should explore materials engineering.

Materials engineers are involved in every stage of a material’s life cycle—from its initial extraction to the recycling of the product it helped create.

At UBC’s Materials Engineering program, you start with the core material groups—metals, ceramics, polymers and composites. By fourth year, you’ll be solving process-design problems and materials-selection solutions for diverse applications in transportation systems, fuel cells, supersonic aircraft, advanced computers, sports equipment and biomedical devices.

Vancouver Campus

Learn more at You UBC's program page or visit us at mtrl.ubc.ca

Why Study This Program

Material engineering graduates are able to work in a variety of different fields. Common areas of focus they can pursue include: sustainability, bioengineering, biomaterials, fuel cells, automobiles, nanomaterials, manufacturing and aerospace.

Courses & Specializations

Students will first complete a foundational first year of engineering and then take specialized courses beginning in second year, once they are placed into their engineering discipline.

In their fourth year, Materials Engineering students have the opportunity to specialize in one of the following areas:

- Manufacturing and performance

- Minerals and metals extraction

- Biomaterials engineering

Here is a sample of the courses Materials Engineering students can take in each year of study:

| Year 2 | |

|---|---|

| MTRL 201 | Technical Communication |

| MTRL 250 | Thermodynamics of Materials I |

| MTRL 263 | Transport Phenomena I - Fluid Mechanics |

| MTRL 280 | Materials in Design |

| Year 3 | |

|---|---|

| MTRL 340 | Manufacturing in Materials Engineering |

| MTRL 358 | Hydrometallurgy I |

| MTRL 378 | Phase Transformations |

| MTRL 394 | Polymer and Polymer Matrix Composites |

| Year 4 | |

|---|---|

| MTRL 471 | Nanofibre Technology |

| MTRL 485 | Failure of Materials |

| MTRL 478 | Electronic Materials |

| MTRL 455 | Economic Aspects of Materials Engineering |

For a more in-depth look at the curriculum, please consult the Academic Calendar and course descriptions.

Enhance Your Education (further education)

Materials Engineering graduates looking to continue their education can pursue professional programs and graduate studies. The analytical and problem-solving skills students gain from an undergraduate engineering degree translate well into the qualities needed for Medical and Law School. These students also make strong candidates for UBC’s Master of Engineering Leadership in Advanced Materials Manufacturing which offers the unique combination of business and engineering courses for students looking to further their studies and gain the relevant skills to create multi-material manufacturing solutions for automotive, aerospace, and manufacturing sectors.

Careers

With a mean base salary of $101,306 (source) and an expected employment growth rate of 1.1% over the next 5 years (source), Materials Engineering graduates are well equipped to pursue successful careers in consulting firms, government, research and education institutions, and mining, metal processing and manufacturing companies (source). Common career titles (source) for Materials Engineering graduates include: corrosion engineer, smelter engineer, refining engineer, material stress engineer and more.

Employers

Both current students and graduates are able to work for a wide range of employers. Some of the biggest employers of UBC Materials Engineering students over the past several years include: Esso, BC Hydro, Toyota, Imperial Oil, SNC – Lavalin, Barrick, US Steel Canada, Stemcell Technologies, TC Energy, National Research Council of Canada and CCMET.

Alumni

Design Teams & Clubs

Design Teams

There are over 30 Engineering Design Teams at UBC. Joining an engineering design team is an excellent opportunity for students from all disciplines to collaborate on a wide variety of design projects and gain relevant teamwork, leadership, and technical skills transferrable to future careers. Design teams related to Materials Engineering include:

See the full list of UBC’s Engineering Design Teams

Research

The Materials Engineering department performs research activities in various facilities on campus including the Advanced Materials Process Engineering Laboratory (AMPEL) and the Clean Energy Research Centre. The department is also involved with initiatives including the Composites Research Network and MagNet – NSERC Magnesium Network. There are eight research groups within the department:

- Advanced Metals Processing:

- The Advanced Metals Processing research group conducts applied and fundamental research in many areas dealing with advanced metal alloys and their processing with a particular focus on light metal alloys intended for critical applications in the automotive and aerospace sectors.

- Biomaterials:

- The Biomaterials Group at the department of Materials Engineering focuses on health-related materials issues. This group is especially interested in developing novel materials with dental, orthopedic, and pharmaceutical applications.

- Ceramics:

- This group is heavily involved in the development of advanced refractories for nonferrous industries (Zn, Pb, Ni, Cu, and others), the development of new castable refractories, in-situ sinterable basic castables, corrosion of refractories in contact with non-ferrous slags, mechano-chemical processing of refractories; mechanical alloying of ceramics; and the evaluation of processing – properties correlations for refractories.

- Composites:

- The Composites Group is an interdisciplinary research group spanning the two departments of Materials Engineering and Civil Engineering at UBC. The group conducts applied and fundamental research in many areas dealing with advanced composite materials and structures, including impact, processing and fracture. Major research funding in the form of contracts and grants is provided by industrial and governmental agencies.

- Corrosion:

- The Corrosion group’s research focus is electrochemical processes with focus on high temperature and pressure applications, corrosion electrochemical synthesis of nano-crystalline materials, aqueous electrometallurgy, hydrometallurgy and fuel cell.

- Hydrometallurgy:

- The Hydrometallurgy Group at the department of Materials Engineering focuses on hydrometallurgy-related materials issues. This group is especially interested in developing novel hydrometallurgy processes and applications.

- Microstructure:

- Microstructure engineering encompasses a broad range of activities with the goal of optimizing the structure and properties of metals and alloys. The group’s approach stresses novel experimental approaches combined with the development of physically based models which are often fully integrated into continuum deformation or temperature models (i.e. FEM models).

- Semiconductors:

- This research has focused on semiconductors to make smaller, faster, lower-cost and more energy efficient computation and communication hardware.

Minors & Dual Degrees

Engineering students are able to complement their studies with 5 Minors available or a Dual Degree with Arts. Students interested in a minor can apply to their chosen option in their third year of study. A minor or dual degree will likely extend your degree past 4 years.

Co-op

Participation in the Engineering Co-op Education program gives students the opportunity to gain up to 20 months of paid relevant work experience during their degree. This experience provides an excellent opportunity for students to explore different industries, apply their studies to the working world, and create connections with future employers. The Co-op program will extend your four-year degree to five years. Participation is optional and students apply to join Co-op in their second year of study.

International Experiences

Students can embark on an unforgettable experience abroad while earning credits towards their engineering studies. Opportunities include the Coordinated International Experience (CIE) exchange program, the Go Global exchange program, and the Global Engineering Leadership courses. The CIE program is customized for Applied Science students and features 18 international partner institutions across 3 regions. All of the international experiences allow students to build an international network of peers, professors, and potential employers.